Bit by Bit researchers have submitted an article in response to a call for papers from the Journal of Industrial Ecology on the environmental dimensions of additive manufacturing and 3D printing. The article, Product life extension through additive manufacturing: The business model implications, is co-authored by Mélanie Despeisse and Simon Ford from the Bit by Bit project, and by Anna Viljakainen from the VTT Technical Research Centre of Finland.

Abstract

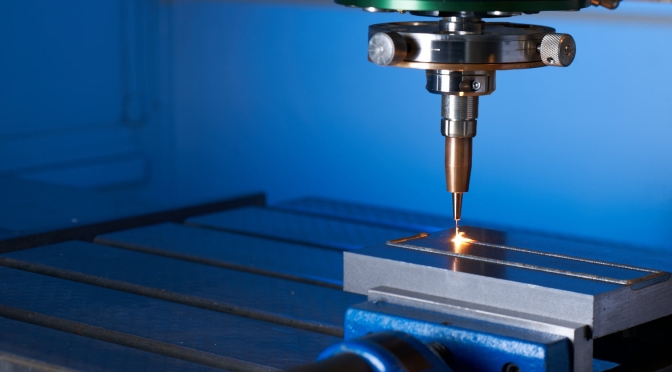

Additive manufacturing has the potential to transform the industrial landscape and to move industry towards more sustainable modes of production and consumption. There is a growing number of examples of products and processes redesigned forAM as companies are beginning to discover the potential benefits of AM across the product life cycle. In this paper we focus on the use and end-of-life phases of the product life cycle to ask: How can the application of additive manufacturing enable product life extension? Three technical approaches to product life extension through AM have been identified: (1) improved durability of products through redesign; (2) production of spare parts using the make-to-order model to enhance companies’ capability to repair and remanufacturing products; (3) direct in-situ repair of worn, damaged and broken parts. With the availability of AM technologies to extend product life, companies may increasingly adopt service-based business models to align with sustainability goals, thereby decoupling the social and economic value created from the environmental impacts of production and consumption. A series of propositions linking this theory to AM and product life extension are developed, providing an agenda for future research in this domain.