We’re pleased to welcome Cecilia Maria Angioletti as a visitor to the Bit by Bit project to continue investigations into the sustainability implications of 3D printing.

Cecilia is currently undertaking her doctoral studies in Management, Economics and Industrial Engineering at Politecnico di Milano, Italy. She gained her Master’s degree with specialisation on production engineering, operations management, corporate strategy and economics. In her Master’s thesis she investigated the location choices of foreign multinational companies through greenfield investments. The implementation of an econometric model supported the empirical analysis.

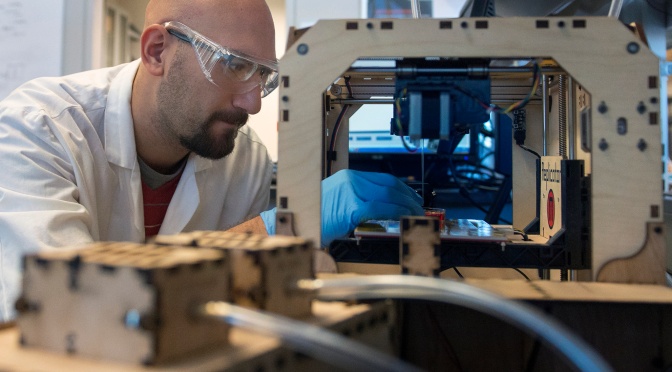

In her current research Cecilia is looking into how industrial systems can become more resource efficient and sustainable. Specifically, she is focusing on the opportunities for improvements offered by additive manufacturing technologies and how adopting these technologies could enable the implementation of the circular economy paradigm. The promise of additive manufacturing can be seen throughout the product lifecycle: it is claimed that it can reduce energy and material consumption through maintenance, re-use, rework recycling, waste reduction strategies that close the loop. For manufacturing firms, it is thought that adopting additive manufacturing technology will provide an opportunity to enhance their sustainability performance through efficiency improvements that both reduce operating costs and improve competitive advantage.

Despite the significant body of research and evaluation methodologies for sustainability, including life cycle analyses, process optimisation, waste management and environmental protection, there remains scare concrete evidence of the resource efficiency benefits of additive manufacturing. Accordingly, Cecilia is probing into these claims, and in her current project she developed a quantitative assessment tool. While she’s with us in Cambridge she’ll use this tool to analyse to what degree the adoption of additive manufacturing supports the more efficient use of materials and energy.

[Image source: Cecilia Maria Angioletti]